Understanding Water in Compressed Air Systems

Water in compressed air results from atmospheric humidity being compressed and cooled, causing condensation. High temperatures during compression exacerbate this, as hot air holds more moisture. Left unchecked, this water can corrode pipes, damage tools, and contaminate products. Water-cooled aftercoolers rapidly cool compressed air, condensing moisture for removal, while air dryers further reduce humidity to protect your system.

- Moisture Sources: Ambient air contains humidity, which condenses when compressed and cooled in the system.

- Compression Heat: Compressors generate heat, increasing airís moisture-holding capacity, leading to condensation.

- Aftercoolers: Water-cooled aftercoolers lower air temperature, condensing water vapor for easy removal.

- Air Dryers: Refrigerated or desiccant dryers remove residual moisture, ensuring dry, clean air.

- System Protection: Removing water prevents corrosion, equipment wear, and product contamination.

- Applications: Manufacturing, food processing, pharmaceuticals, and automotive industries require dry air.

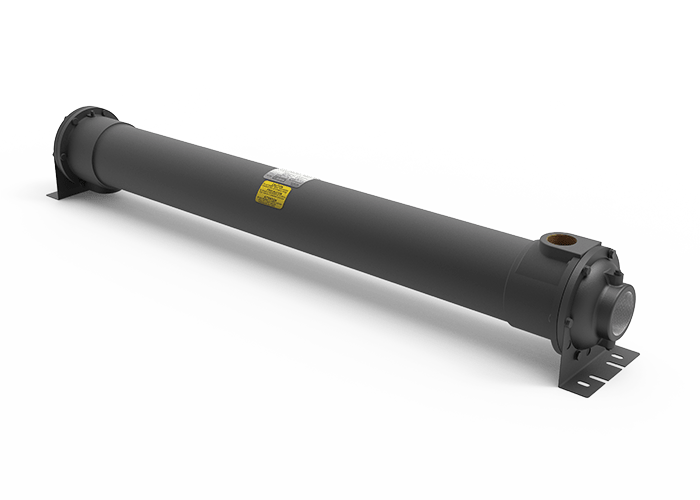

Water-Cooled Aftercoolers:

Compressed Air Cooling

- High-Efficiency Cooling

- Corrosion-Resistant Materials

- Custom and Stock Units

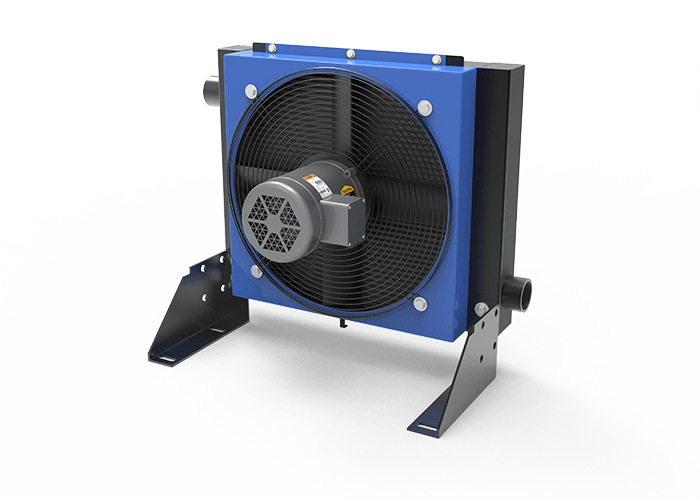

Air-Cooled Aftercoolers:

Compressed Air Cooling

- AC, DC and Air Motor Options

- Industrial & Mobile Applications

- Custom and Stock Units

Preventing Water in Compressed Air

Effective water removal enhances system efficiency and longevity. Water-cooled aftercoolers cool compressed air to condense moisture, which is then drained. Air dryers further reduce humidity, preventing corrosion and contamination. These solutions lower maintenance costs and ensure consistent performance across industries like manufacturing and food processing.

Implementing aftercoolers and dryers is critical for compliance with air quality standards and protecting equipment. Our robust systems are designed for reliability, helping you maintain dry, high-quality compressed air for optimal operations.