Air-Cooled Compressed Air Coolers

Highly efficient air cooled after coolers are a cost effective solution to remove water vapor and cool compressed air, to safe, usable levels for many applications.

Low Approach Temperature:

The superior design of the aftercoolers ensures that the compressed air will be cooled to your desired approach temperature. This outstanding performance combined with the high efficiency of a moisture separator will ensures the maximum removal of moisture from the compressed air.

Low Approach Temperature:

Aftercoolers are designed to withstand high temperatures. This ensures problem-free service under the most demanding operating conditions.

Low Operating Cost:

Air cooled aftercoolers offer the lowest total operating cost.

Air-Cooled Compressed Air Heat Exchangers

AHP Series:

Air-Cooled Aftercooler

- Brazed Aluminum Core/ Bar & Plate

- High Performance

- High Flows: 400-3,500 CFM

AOL Series:

Air-Cooled Aftercooler

- Brazed Aluminum Core/ Bar & Plate

- Full Line of Sizes & Features

- High Flows: 400-3,500 CFM

AA Series:

Air-Cooled Aftercooler

- Full Line of Sizes & Features

- Energy Efficienct

- Medium Flows 80-300 CFM

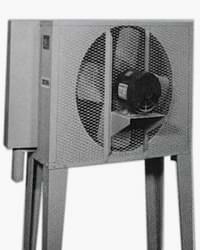

ACOC Series:

Air-Cooled Aftercooler

- Combination Welded Cores (Air/Oil)

- Vertical Air Flow / Compact Design

- Excellent for Field Conversions

UPA Series:

Air-Cooled Aftercooler

- Full Line of Sizes and Features

- High Performance

- High Flows 400-3,500 CFM

Air Belt Guard Aftercoolers:

Air-Cooled Aftercooler

- Uses Existing Air Flow

- Easy to Install

- Rugged Construction

HiRoss Aftercoolers:

Air-Cooled Aftercooler

- Energy Efficient

- Full Line of Sizes & Features

- Rigid and Durable Air In/Out Conn.

IPAC Aftercoolers:

Industrial Applications

- Heavy Duty, Compact Design

- Low Energy Cost

- Rigid and Durable Air In/Out Conn.

- Abrasive Blasting Aftercoolers

- AC Powered Aftercoolers

- Air-Cooled Aftercoolers

- Agriculture Aftercoolers

- Bead Blasting Aftercoolers

- Belt Guard Aftercoolers

- Chemical and Petrochemical Aftercoolers

- Construction and Mining Aftercoolers

- DC Powered Aftercoolers

- Dry Ice Blasting Aftercoolers

- Food & Beverage Aftercoolers

- High Pressure Air Blasting Aftercoolers

- Injection Molding Aftercoolers

- Instrument Air Aftercoolers

- Marine and Vessel Aftercoolers

- Micro-Abrasive Blasting Aftercoolers

- Painting & Spraying Aftercoolers

- Pharmaceutical Aftercoolers

- Piston Compressor Aftercoolers

- Plastic Media Blasting PMB Aftercoolers

- Pnneumatic Aftercoolers

- Pneumatic Machinery Aftercoolers

- Pneumatic Tool Aftercoolers

- Polymeric Blasting Aftercoolers

- Reciprocating Compressor Aftercoolers

- Rotary Screw Compressor Aftercoolers

- Sandblasting Aftercoolers

- Sintered Bead Blasting Aftercoolers

- Soda Blasting Aftercoolers

- Spray Painting Aftercoolers

- Textiles & Printing Aftercoolers

- Water Cooled Aftercoolers