Aftercooler Accessories

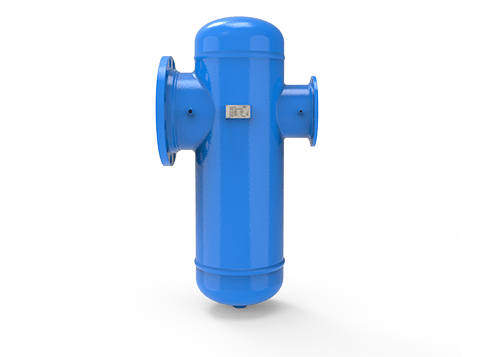

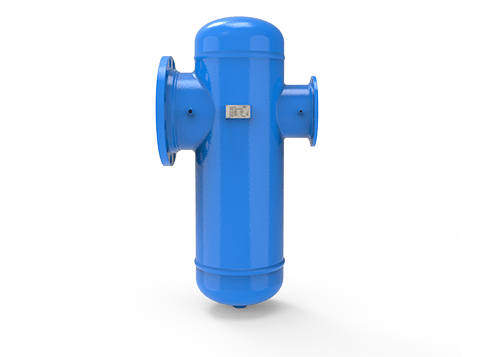

Moisture Separators: Moisture Separators and Float Drains are the final step in removing moisture from compressed air after its been cooled and has condensed. Compressed air is spun thru a centrifugal separator whereby the remaining suspended moisture collects against the walls of the unit and falls down toward the drain / trap. Moisture separators must be mounted in a vertical configuration.

Float Drains: Once the moisture has been separated from the compressed air, a float drain either automatically or manually discharges the liquid while maintaining the pressure of the compressed air system.

Water Separators:

Efficient Moisture Removal

- Flows 5 - 3,500 SCFM

- 200 PSI Maximum

- Automatic Float Style Drain (optional)

Float Drains:

Manual and Auto Drains

- Automatic Condensate Drain

- Cast Zinc Construction

- 200 PSI Maximum

- Abrasive Blasting Aftercoolers

- AC Powered Aftercoolers

- Air-Cooled Aftercoolers

- Agriculture Aftercoolers

- Bead Blasting Aftercoolers

- Belt Guard Aftercoolers

- Chemical and Petrochemical Aftercoolers

- Construction and Mining Aftercoolers

- DC Powered Aftercoolers

- Dry Ice Blasting Aftercoolers

- Food & Beverage Aftercoolers

- High Pressure Air Blasting Aftercoolers

- Injection Molding Aftercoolers

- Instrument Air Aftercoolers

- Marine and Vessel Aftercoolers

- Micro-Abrasive Blasting Aftercoolers

- Painting & Spraying Aftercoolers

- Pharmaceutical Aftercoolers

- Piston Compressor Aftercoolers

- Plastic Media Blasting PMB Aftercoolers

- Pnneumatic Aftercoolers

- Pneumatic Machinery Aftercoolers

- Pneumatic Tool Aftercoolers

- Polymeric Blasting Aftercoolers

- Reciprocating Compressor Aftercoolers

- Rotary Screw Compressor Aftercoolers

- Sandblasting Aftercoolers

- Sintered Bead Blasting Aftercoolers

- Soda Blasting Aftercoolers

- Spray Painting Aftercoolers

- Textiles & Printing Aftercoolers

- Water Cooled Aftercoolers