AC Powered Aftercoolers

These units rely on alternating current (AC) to drive their motors, distinguishing them from DC-powered counterparts that use direct current. The choice between AC and DC power impacts design, efficiency, and application suitability.

AC-powered aftercoolers typically employ induction motors, the most common type due to their durability, low maintenance, and compatibility with standard industrial power grids (e.g., 120V or 480V, 60Hz). Single-phase induction motors suit smaller units, while three-phase versions power larger, high-capacity aftercoolers, offering greater efficiency and smoother operation. These motors drive fans that force ambient air over finned tubes, dissipating heat from the compressed air.

In contrast, DC-powered air-cooled aftercoolers use direct current motors, such as brushed or brushless types. Brushed DC motors are simpler and cost-effective, often found in portable or off-grid units powered by alternators, generators or straight from the batteries.

Key differences arise in power availability and control. AC units integrate seamlessly into fixed industrial settings with stable grids, while DC units adapt to variable or renewable energy sources. AC motors generally handle higher loads with less complexity in wiring, whereas DC systems may require inverters or rectifiers, adding cost. Efficiency-wise, three-phase AC induction motors often outperform DC motors in continuous operation, though BLDC motors narrow this gap. Ultimately, the choice hinges on application, infrastructure, and operational demands.

Air-Cooled Compressed Air Heat Exchangers

AHP Series:

Air-Cooled Aftercooler

- Brazed Aluminum Core/ Bar & Plate

- High Performance

- High Flows: 400-3,500 CFM

AHPH Series:

Air-Cooled Aftercooler

- Brazed Aluminum Core/ Bar & Plate

- High Performance

- High Flows: 400-3,500 CFM

AOL Series:

Air-Cooled Aftercooler

- Brazed Aluminum Core/ Bar & Plate

- Full Line of Sizes & Features

- High Flows: 400-3,500 CFM

AA Series:

Air-Cooled Aftercooler

- Full Line of Sizes & Features

- Energy Efficienct

- Medium Flows 80-300 CFM

CC Series:

Air-Cooled Aftercooler

- Full Line of Sizes & Features

- Energy Efficienct

- Medium Flows 80-300 CFM

ACOC Series:

Air-Cooled Aftercooler

- Combination Welded Cores (Air/Oil)

- Vertical Air Flow / Compact Design

- Excellent for Field Conversions

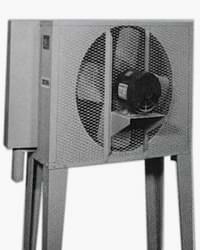

UPA Series:

Air-Cooled Aftercooler

- Full Line of Sizes and Features

- High Performance

- High Flows 400-3,500 CFM

HiRoss Aftercoolers

Air-Cooled Aftercooler

- Energy Efficient

- Full Line of Sizes & Features

- Rigid and Durable Air In/Out Conn.

IPAC Aftercoolers

Industrial Applications

- Heavy Duty, Compact Design

- Low Energy Cost

- Rigid and Durable Air In/Out Conn.

- Abrasive Blasting Aftercoolers

- AC Powered Aftercoolers

- Air-Cooled Aftercoolers

- Agriculture Aftercoolers

- Bead Blasting Aftercoolers

- Belt Guard Aftercoolers

- Chemical and Petrochemical Aftercoolers

- Construction and Mining Aftercoolers

- DC Powered Aftercoolers

- Dry Ice Blasting Aftercoolers

- Food & Beverage Aftercoolers

- High Pressure Air Blasting Aftercoolers

- Injection Molding Aftercoolers

- Instrument Air Aftercoolers

- Marine and Vessel Aftercoolers

- Micro-Abrasive Blasting Aftercoolers

- Painting & Spraying Aftercoolers

- Pharmaceutical Aftercoolers

- Piston Compressor Aftercoolers

- Plastic Media Blasting PMB Aftercoolers

- Pnneumatic Aftercoolers

- Pneumatic Machinery Aftercoolers

- Pneumatic Tool Aftercoolers

- Polymeric Blasting Aftercoolers

- Reciprocating Compressor Aftercoolers

- Rotary Screw Compressor Aftercoolers

- Sandblasting Aftercoolers

- Sintered Bead Blasting Aftercoolers

- Soda Blasting Aftercoolers

- Spray Painting Aftercoolers

- Textiles & Printing Aftercoolers

- Water Cooled Aftercoolers