Compressed Air Dryer Solutions

Moisture Removal

Compressed air contains moisture that can damage equipment, cause corrosion, and compromise product quality. Our air dryers effectively remove water vapor, delivering dry, clean air to protect your systems and ensure operational reliability.

Refrigerated Dryers

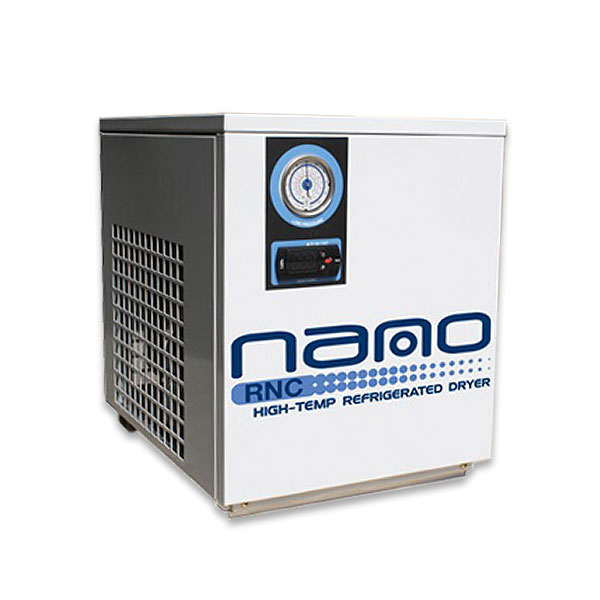

Our refrigerated air dryers cool compressed air to condense and remove moisture, making them ideal for general industrial applications. These energy-efficient systems are compact, reliable, and designed for consistent performance with minimal maintenance.

By maintaining a low dew point, refrigerated dryers prevent water buildup in pipelines and equipment, extending the lifespan of your compressed air system and reducing operational costs.

Desiccant Dryers

For applications requiring extremely low dew points, our desiccant air dryers use adsorbent materials to remove moisture from compressed air. These dryers are perfect for sensitive industries like pharmaceuticals, food processing, and electronics.

Desiccant dryers are built for durability and efficiency, with advanced regeneration systems that minimize energy consumption while ensuring consistent air quality.

Membrane Dryers

Our membrane air dryers offer a compact, maintenance-free solution for moisture removal. Using selective permeation, these dryers are ideal for remote or space-constrained applications, providing reliable performance without the need for electricity.

Refrigerated Dryers

General Applications

- Energy Efficient

- Low Dew Point

- Compact Design

Desiccant Dryers

Medical and Electronics Applications

- Ultra-Low Dew Point

- High Reliability

- Energy-Saving Regeneration

High Temperature Dryers

Industrial Applications

- Maintenance-Free

- Compact and Lightweight